20 Jan “Forever Chemicals” Remediation Technologies

Reading Time: 4 minutesRegulations by federal and state agencies mandate that certain property owners/responsible parties must remediate PFAS to below ultra-low (parts per trillion) cleanup levels. Although remediation technologies continue to evolve, there are some current proven technologies that will meet these ultra-low standards. What are your options?

Background

The class of compounds known as per- and polyfluoroalkyl substances (PFAS), also referred to as “forever chemicals,” has become an increasingly hot topic and growing concern in the environmental and insurance industries. The NJDEP has established PFAS as an emerging contaminant in the state of New Jersey based on the abundant literature that shows it poses adverse health effects at ultra-low concentrations (in the parts per trillion) in soil and water. The most concerning and persistent PFAS compounds were phased out of industrial use in the United States in the early 2000s. Their use in many types of consumer products was widespread due to their unique properties. These properties include water and oil repellency (stain resistant fabrics), chemical resistance (non-stick cookware), and thermal stability (outdoor gear and protective clothing). Unfortunately, those same properties that made PFAS beneficial in consumer applications now make it a vexing challenge for environmental professionals to remediate in soil and groundwater.

While research on PFAS remedial technologies is relatively new and ongoing, some technologies have demonstrated success in field applications at multiple sites. These remedial methods are not a “one size fits all” solution. For each property, a remediation plan must be carefully developed based on site-specific conditions and factors, such as the extent of contamination, the type of PFAS contaminants, the commingling of non-PFAS compounds within the contaminant plume, and the efficacy of the selected technology for the intended application.

Soil Remedial Options

PFAS contamination is found in both soil and water. Once in water, PFAS’s high mobility and tendency to spread over wide areas poses exposure risks to nearby drinking water supplies and other human receptors. Therefore, treatment of “source” PFAS soils is important to eliminate any direct contact exposure and prevent further leaching of PFAS contaminants into groundwater. For soil contamination, traditional excavation and off-site disposal of PFAS-impacted soils can be utilized. However, landfill operators are becoming more concerned with their own PFAS liability and, consequently, PFAS disposal costs are skyrocketing. Therefore, different technologies to clean soil onsite may make the most sense. These technologies include soil washing, immobilization/stabilization, and incineration.

Groundwater Remedial Options

Sorption Technologies

Sorption technologies can remove PFAS contaminants from a medium by binding or adhering the contaminant to a different surface. Among the most common and generally effective methods of sorption used at contaminated properties are carbon adsorption and ion exchange.

Adsorption: Adsorption describes the attachment of PFAS molecules to the surface of a solid material. Granular Activated Carbon (GAC) is most often used to remove PFAS contaminants from water through adsorption, leveraging its high surface area and porous structure to capture the contaminants. GAC has long been used to adsorb contaminants from groundwater. As discussed above, the effectiveness of any remediation technique depends on several site-specific factors that must be evaluated. For example, this method has shown to be more effective in remediation of longer-chain PFAS compounds, as they are generally easier to adsorb than shorter-chain PFAS molecules due to the differences in their chemical structures/properties.

Ion exchange (IX): During the ion exchange process, PFAS ions in the water are exchanged with harmless ions from the treatment medium. When contaminated water flows through the ion exchange resin, the harmful PFAS ions are captured on the resin and immobilized. This occurs because (by design) the negatively charged PFAS molecules are attracted to the positively charged functional groups on the resin’s surface. The resin, in turn, releases harmless ions (such as chloride) into the water.

In field applications for groundwater, both of the above-described methods typically require an “ex-situ” pump-and-treat groundwater extraction system whereby contaminated water is withdrawn from the impacted aquifer and treated using ion exchange or GAC. Subsequently, the treated water is either returned to its original source or is discharged, normally to a sewage treatment plant. In either case, a discharge permit is required.

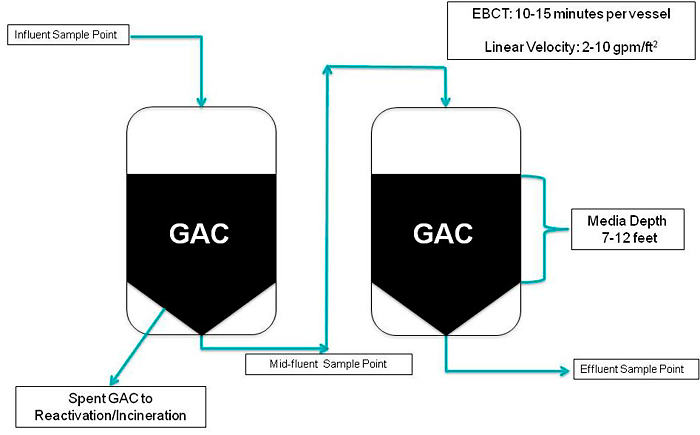

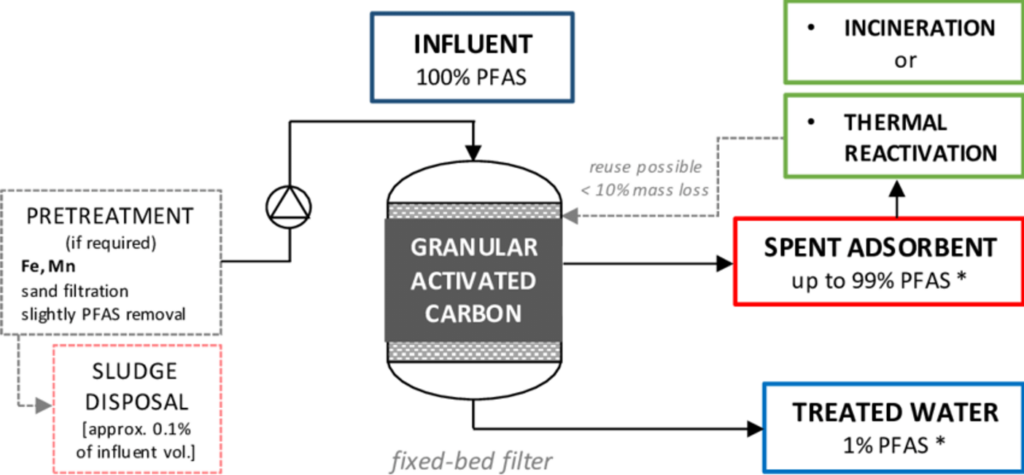

As illustrated in both diagrams below (Fig. 1 and Fig. 2), GAC and IX technology have a similar methodology, which involves running the contaminated water through a series of filtration units that remove the PFAS. In GAC systems, water flows through a bed of activated carbon where contaminants are adsorbed, while in IX systems, water passes through resin beads that facilitate the ion exchange. For some sites, it may be effective to utilize both ion exchange and GAC techniques in tandem to maximize PFAS removal efficiency.

Fig. 1 — Image Source: Interstate Technology & Regulatory Council (ITRC)

Fig. 2 — Image Source: Interstate Technology & Regulatory Council (ITRC)

The success of these sorption technologies may also be influenced by the influent’s water quality parameters, such as pH, temperature, and the presence of competing ions. As a result, pretreatment steps — such as coagulation, precipitation, and filtration — may be necessary to optimize the efficiency of these sorption processes, as shown in the flow diagram below.

While sorption technologies have proven effective, there are important considerations and potential drawbacks. One concern is the management of spent media after treatment. Options for handling spent media include disposal, regeneration, and thermal treatment. Other limitations may include the initial cost of deployment and the need for regular monitoring to ensure continued effectiveness. Lastly, pump-and-treat technologies for almost all types of contaminants in groundwater are expensive and time consuming.

Fig. 3 — Image Source: Review of water treatment systems for PFAS removal (Riegel et. Others)

As regulations surrounding PFAS become more stringent, understanding the available remediation technologies and their site-specific applicability is crucial to effectively address this emerging threat. But there are reasons for optimism. First, ESA always considers alternate strategies with the intent to obviate onsite treatment. If treatment cannot be avoided, there are other, potentially less expensive, treatment methods now being developed. Following is a partial list of technologies currently in pilot treatment phase or full-scale use.

- Sorption

- Membrane nanofiltration

- Bioremediation

- Redox Manipulation

- Thermal Desorption/Destruction

- Soil Washing

- Chemical Oxidation

- Electrochemical Treatment

For additional information on treatment technologies, please visit ITRC’s PFAS page. And, as always, feel free to Ask ESA to help manage your PFAS challenges and any other regulatory compliance needs.